- Product Describe

-

Instruction Manual for the "New Standard" Heavy-Duty Dynamic Penetrometer

1. General Provisions

(1) The cone penetration test is suitable for gravelly soils, sandy soils, and cohesive soils. It can be used to evaluate the density of foundation soils, as well as to determine the deformation modulus and bearing capacity of the foundation soil.

(2) Cone penetration tests can be categorized into light-duty cone penetration tests, heavy-duty cone penetration tests, and extra-heavy-duty cone tests.

There are three types of dynamic probing.

(3) No fewer than 3 cone penetration test boreholes should be conducted at the same site, and each soil layer should have no fewer than 6 test points.

2 Testing Equipment

(1) The cone penetration test equipment should consist of a drop hammer, probe, hammer pad, guide rod, and penetration rod.

The drop hammer, probe, hammer pad, guide rod, and penetration rod should all be made of corrosion- and wear-resistant steel, with specifications complying with the requirements specified in Table 2.2.

Table 2.2 Main Technical Parameters of Cone Dynamic Penetration Test Equipment

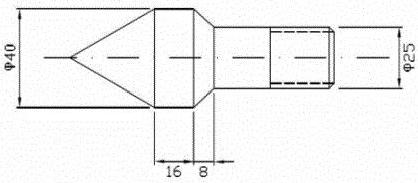

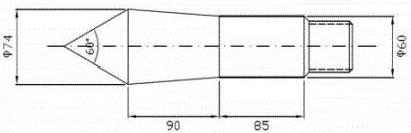

Type Lightweight Heavy-duty Super-heavyweight Drop hammer Quality (kg) 10 ± 0.1 63.5 ± 0.5 120 ± 1 Drop distance (mm) 500 ± 20 760 ± 20 1000 ± 20 Probe Taper end diameter (mm) 40 74 74 Cross-sectional area (cm²) 12.6 43 43 Cone Angle (°) 60 60 60 Probe Rod Diameter (mm) 25 ± 0.5 42 ± 0.5 50 to 60 Indicator Penetration reading N at 30 cm. Penetration 10 cm reading: Nas Penetration reading at 10 cm: N2a (3) The external dimensions of the light-duty cone penetration test (CPT) probe shall comply with the specifications shown in Figure 2.3-1, while the external dimensions of the heavy-duty and extra-heavy-duty CPT probes must adhere to the requirements outlined in Figure 2.3-2. After surface quenching, the hardness of the probe should exceed HRC40, and the maximum wear dimension of the probe diameter should not exceed 2 mm. Similarly, the maximum wear dimension of the cone tip height should also be no greater than 5 mm.

Figure 2.3-1: External Dimensions of the Lightweight Cone Penetrometer Probe (Dimension Unit: mm)

Figure 2.3-2: External Dimensions of Heavy and Ultra-Heavy Cone Penetration Test Probes (Dimensions in mm)

(4) The tensile strength of the probing rod should exceed 600 MPa. The probing rod must be straight, all component connections should have intact threads, and the joints must be securely fastened.

(5) The hammer pad diameter should be less than half the diameter of the falling hammer, yet greater than 100 mm. The length of the guide rod must meet the requirements for drop height. The hammer

The combined mass of the pad and guide rod should not exceed 30 kg: The central axes of the hammer pad, guide rod, and probing rod must be aligned in a straight line.

(6) The drop hammer should be cylindrical, with a height-to-diameter ratio of 1 to 2. The diameter of the central circular hole in the drop hammer should be 3 to 4 mm larger than the outer diameter of the guide rod.

(7) The cone penetration test equipment should be equipped with an automatic release mechanism to ensure the free fall of the hammer; the hammer should be calibrated regularly, and the drop height of the hammer must be checked before each test.

3. Test Method

(1) Before conducting the cone penetration test, inspect the equipment to ensure that all components meet the required specifications. If any component shows wear or deformation exceeding the specified limits, it should be replaced or repaired.

(2) Equipment and machinery should be securely installed, with supports remaining stable during operation. All threaded connections between components must be tightly fastened.

(3) During the test, first drill to the predetermined test depth using the drilling tool, then gently lower the dynamic penetration probe to the bottom of the borehole—impact is strictly prohibited.

Strike or press into the soil layer for testing.

(4) During cone penetration testing, maintain the verticality of the probe rod and guide rod after they are connected. Ensure that the hammer always falls vertically along the guide rod to prevent eccentric hammering, tilting of the probe rod, or lateral swaying. The hammering frequency should be controlled within the range of 15 to 30 strikes per minute.

(5) The lightweight cone penetration test shall comply with the following provisions:

1 During lightweight cone penetration tests, the test soil layer should be continuously penetrated downward.

2. When performing continuous penetration tests, the drop height of the center-punching hammer should be 50 cm, allowing it to fall freely, with the hammer pad positioned at a height above the borehole opening.

Not to exceed 1.5 m

3 The number of hammer blows required to penetrate 30 cm is used as the test criterion, denoted by N. When encountering dense soil layers, penetration continues until 30 cm is achieved.

When the number of hammer blows exceeds 90, or when the number of blows required to penetrate 15 cm surpasses 45, the test may be stopped.

(6) Heavy-duty and ultra-heavy-duty cone penetration tests shall comply with the following provisions:

1 The drop height for the heavy-duty cone penetration test should be 76 cm; the drop height for the extra-heavy-duty cone penetration test should…

The 100-cm drop hammer should fall freely along the guide rod, and the height of the hammer pad from the hole opening should not exceed 1.5 m.

2 The hammer blows should be delivered continuously; both the heavy-duty cone penetration test and the extra-heavy-duty cone penetration test should be conducted at 10 cm intervals per penetration.

The number of hammer strikes is used as the test indicator, represented by Ness and N₂o, respectively.

3 Heavy-duty and extra-heavy-duty cone penetration tests can be used interchangeably depending on changes in stratum strength. Heavy-duty cone penetration test

When the measured number of blows exceeds 50 blows per 10 cm during testing, it is recommended to switch to the extra-heavy-duty cone penetration test; the heavy-duty cone penetration test

When the measured number of blows in a penetration test is less than 5 blows per 10 cm, the extra-heavy cone dynamic penetration test should not be used.

4. The test can be conducted in segments within the borehole, and each test segment should be carried out continuously without any interruptions in between.

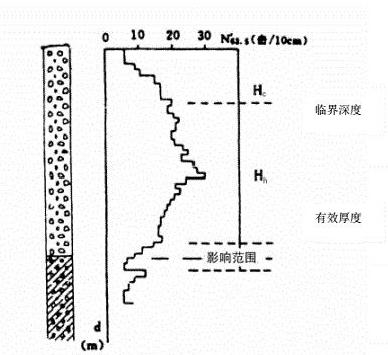

Figure 6.4.7: Curve Showing the Relationship Between Modified Cone Penetration Test Blow Counts and Penetration Depth

4. When the effective thickness of the soil layer is less than 0.3 m, the average number of blows from the heavy cone penetration test can be determined according to the following principles:

(1) When both the upper and lower layers consist of soils with relatively low blow counts, N₆₃₅ can be taken as the larger of the two soil layer's standard penetration test blow counts, Ne₃smax.

(2) When both the upper and lower layers are soils with relatively high blow counts, N₆s should be taken as the smaller value between this layer’s standard penetration test blow count and Neas mn.

(3) The characteristic value of bearing capacity for cohesive soil, fo, can be determined based on the Nro values of the site’s soil layers when the penetration depth is less than 4 meters.

Table 4.3.3: Confirmed.

Table 4.3.3: Characteristic Value of Bearing Capacity for Clayey Soil, fan (kPa)

N₁o (Height 130cm) 15 20 25 30 FAO 100 140 180 220 Note: Values in the table can be linearly interpolated.

(4) The characteristic values of bearing capacity, \( f_o \), for medium sand, coarse sand, gravelly sand, and gravelly soil foundations formed by alluvial and fluvial processes can be determined according to Table 4.5-1 and Table 4.5-2, based on the Ness values of the site soil layers [as shown in the figure], provided that the penetration depth is less than 20 meters.

(5) For medium sand, coarse sand, gravelly sand, and crushed-stone foundations with origins in alluvial or fluvial deposits, the characteristic value of bearing capacity, Ja, can be determined according to Table 4.5-1 and Table 4.5-2 based on the Na values of the site soil layers, provided that the penetration depth is less than 20 meters.

Table 4.5-1 shows the characteristic values of bearing capacity for sand, rented sand, and gravelly sand (kPa).

Ms. (Shoot/10m) 3 4 5. 6 7 8 9 10 f 120 150 180 2m 260 300 340 380 Note: This table generally applies to alluvial and colluvial sandy soils; however, for medium- and coarse-grained sands, the coefficient of uniformity should not exceed 6, while for well-graded sands, it should remain below 20.

Table 4.5-2: Characteristic Value of Bearing Capacity for Gravel Soil / (tPs)

Na: (Hit / 10m) 3 5 6 7 8 9 10 12 14 5 140 170 200 240 20 320 360 400 480 540 a: (Impact / 10 cm) 16 18 20 22 24 26 28 30 35 40 f 600 660 720 780 830 870 900 980 970 1.000 (6) For deformed modulus E of pebbles and rounded gravel formed by alluvial and fluvial processes, when the penetration depth is less than 12 meters, it can be determined according to the Na values of the site’s soil layers, as specified in Table 4.6-1.

Table 4.6-1: Deformation Modulus E Values (MPa) for Pebbles and Gravel Clasts

(Hit / 10 cm) 3 4 5 6 8 10 12 14 16 5 9 1 14 17 22 27 31 36 40 (Hit / 10 cm) 18 20 222 24 25 28 30 35 40 E 44 47 50 56 58 60 64 66 4.7 Based on the number of blows N from the heavy and extra-heavy cone penetration tests, as well as Nm, the density of gravelly soil can be determined according to Table 4.7-1 and Table 4.7-2. Note that the values Na and Nm in the tables should be corrected in accordance with this code.

Table 4.7-1: Classification of Gravel Soil Density Using Heavy Cone Penetration Test

Na, (hit / 10 cm) Na; ≤5 5Na, ≤10 10 < Nas ≤ 20 Nas > 20 Density Loose Slightly dense Medium-density Dense Note: This table applies to gravelly soils with an average particle size equal to or less than 50 mm and a maximum particle size smaller than 100 mm.

Table 4.7-2: Classification of Gravel Soil Density Using Ultra-Heavy Cone Penetration Test

Nm (Impact/10 cm) N<3 3 ≤ N ≤ 6 6 N>11 Density Loose Slightly dense Medium-density Dense Note: This table applies to gravelly soils with an average particle size greater than 50 mm or a maximum particle size exceeding 100 mm.

Company Profile

Hebei Yinfeng Experimental Instrument Co., Ltd. is a high-tech enterprise dedicated to the research and development, production, and sales of experimental instruments. The company is headquartered in Hebei Province, relying on the strong industrial foundation and technological innovation resources in the Beijing Tianjin Hebei region. It is committed to providing high-precision and high reliability testing equipment and solutions for material testing, engineering quality control, scientific research experiments and other fields.

Customized Delivery Process

We provide customers with full-process services ranging from pre-sale consultation, customized solution design, equipment installation and commissioning to after-sale technical support.

Online Communication

Provide Custom Drawings

Merchant Quotation

Sign A Contract

Processing And Production

Packaging And Distribution

Confirm Receipt Of Goods

Successful Transaction

Previous:

Probe Tester

If you need customized products, Contact US !

Category

Tag list

Request a Quote

We will contact you within one working day. Please pay attention to your email.

Related Products

Content update in progress