- Product Describe

-

Overview

This instrument meets GB/T3810.3-2016 and ISO10545-3-1995 standards for measuring water absorption, apparent porosity, apparent relative density, and bulk density using the vacuum method. It is used to determine the water absorption, apparent porosity, and bulk density of daily-use ceramics, sanitary ceramics, electrical ceramics, and refractory materials. It also complies with the measurement conditions of GB/T3299-2011 "Method for Determining Water Absorption of Daily-use Ceramics." This instrument can also be used to measure the water absorption of bricks, tiles, and cement products.

Main Technical Specifications

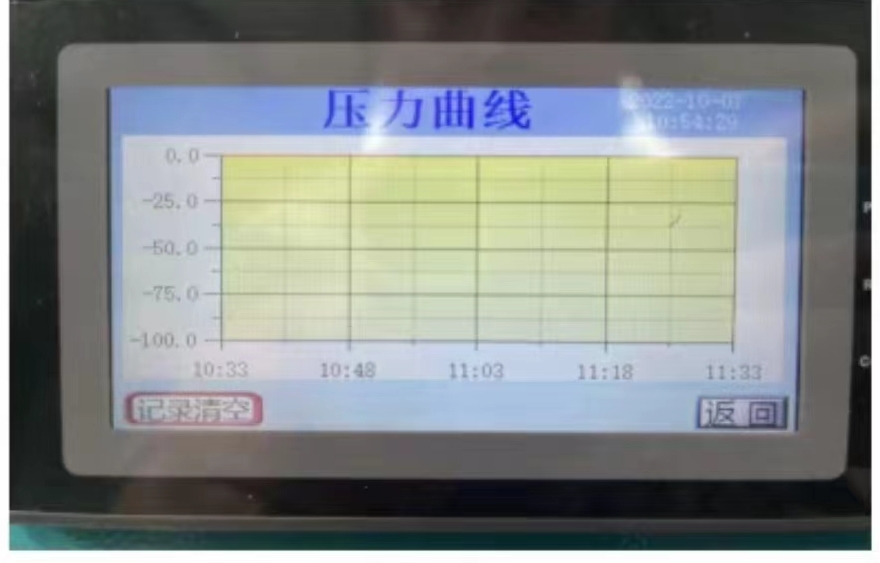

Vacuum degree: local atmospheric pressure (unit MPa) minus 0.01 MPa.

Volume: Φ300X300mm

Vacuum pumping time: adjustable from 0 to 99 minutes

Water injection time: adjustable from 0 to 99 minutes

Repeatability error: <5%.

Voltage: 220V, 50Hz

Digital time display

Structure and Composition of the Instrument

This instrument adopts a mechatronic structure, consisting of a vacuum container, vacuum pump, vacuum air injection valve, electromagnetic water inlet valve, drain valve, and digital controller.

Testing Principle of the Instrument

This instrument uses a fully automatic digital control system. According to technical requirements, the pre-vacuum time, holding time, and water injection time are set. After the sample prepared according to the test method is dried to constant weight and weighed as m1, it is placed into the vacuum container. The air injection valve and drain valve are closed. The vacuum pump is started to pre-vacuum the container. When the vacuum degree reaches the required level,

it is maintained at this vacuum degree for a certain period. After the holding time, the water injection time begins. The air injection valve and drain valve are opened, returning the distilled water in the vacuum container back to the distilled water container. The vacuum container lid is removed, the sample is taken out, surface water is wiped off, and weighed (m2). The measurement results of each sample are recorded, and then the water absorption of the ceramic tile is calculated.

Related Instruments to be Equipped in the Laboratory

1. Oven capable of operating at 110°C ± 5°C

Balance capable of weighing with an accuracy of 0.01% of the sample mass

Deionized water or distilled water.

Usage Method and Operating Steps

Open the back cover, remove the packaging straps tied to the water tank, check whether the connecting pipes beside the water tank are loose, and whether electrical board components are detached. After inspection, add distilled or deionized water into the plastic basin holding the distilled water. The water in the basin should be enough to fill the vacuum barrel. The water inlet pipe with the solenoid valve must be inserted to the bottom of the basin for each test. The vacuum pump barrel should also be filled with water.

Sample Preparation

Test 10 whole bricks for each type.

If the surface area of each brick is greater than 0.04 m², only 5 whole bricks are needed for testing. If the surface area of each brick is greater than 0.16 m², at least 3

whole bricks should be cut in the middle to produce 5 smaller samples with a side length of 100 mm.

If the mass of each brick is less than 50 g, enough bricks should be used so that each test sample reaches 50~100 g. When the side length of the brick is greater than 200 mm, it can be cut into smaller pieces, but each cut piece should be included in the measurement. For polygonal and other non-rectangular bricks,

their length and width are calculated as rectangles.

Dry the bricks in an oven at 110°C ± 5°C to constant weight, i.e., the difference between two consecutive weights measured every 24 hours is less than 0.1%. Cool the bricks to room temperature in a desiccator containing silica gel or other desiccants; acidic desiccants must not be used. Each brick is weighed and recorded according to the measurement accuracy in Table 1.

Measurement Accuracy, g

50 ≤ m < 100 0.02

100 < m ≤ 500 0.05 500 < m < 1000 0.25 1000 < m ≤ 3000 0.50

m > 3000 1.00

Testing

Place the bricks vertically into the vacuum barrel so that they do not touch each other. Place the high-pressure gasket properly and flat, then cover with the acrylic lid. Set the vacuum pumping time (about a few minutes), water injection time (about 120 seconds), add enough water to cover the bricks and exceed by 5 cm. The water addition time depends on actual conditions. Set the soaking time to 15 minutes. After setting the above parameters, turn on the power switch and press the test button to automatically start the test phase and begin vacuum pumping. If the vacuum cannot be drawn (vacuum degree does not change), press down the acrylic lid with both hands until the vacuum degree starts to change. When an alarm sounds, open the drain valve (on the left side of the instrument) to inject air into the vacuum container and return the distilled water to the distilled water container. Remove the vacuum container lid, take out the sample, wring a piece of wet chamois leather by hand, place it on the platform, and gently wipe the surface of each brick. For uneven or embossed surfaces, use the chamois leather to quickly wipe off surface water, then immediately weigh m2. Record the measurement results of each sample, then calculate the water absorption of the ceramic tile, maintaining the same accuracy as in the dry state.

Settings

Vacuum time is adjustable from 0 to 99 minutes (preset at factory, generally no need to change). Water supply time is adjustable from 0 to 99 minutes, factory default is 180 seconds, which can be adjusted according to actual conditions. Soaking time (static time) is adjustable from 0 to 99 minutes, factory default is 15 minutes. Vacuum pressure default is 90 KPa, parameters can be set according to test requirements.

Maintenance and Precautions of the Instrument

1. Install the instrument in a dry and stable place.

2. Keep the instrument clean regularly.

3. Pay attention to whether each pipeline is leaking. If any leakage is found, it must be replaced; otherwise, the vacuum degree cannot be guaranteed.

Company Profile

Hebei Yinfeng Experimental Instrument Co., Ltd. is a high-tech enterprise dedicated to the research and development, production, and sales of experimental instruments. The company is headquartered in Hebei Province, relying on the strong industrial foundation and technological innovation resources in the Beijing Tianjin Hebei region. It is committed to providing high-precision and high reliability testing equipment and solutions for material testing, engineering quality control, scientific research experiments and other fields.

Customized Delivery Process

We provide customers with full-process services ranging from pre-sale consultation, customized solution design, equipment installation and commissioning to after-sale technical support.

Online Communication

Provide Custom Drawings

Merchant Quotation

Sign A Contract

Processing And Production

Packaging And Distribution

Confirm Receipt Of Goods

Successful Transaction

Previous:

Ceramic Tile Water Absorption Tester

If you need customized products, Contact US !

Category

Tag list

Request a Quote

We will contact you within one working day. Please pay attention to your email.

Related Products

Content update in progress