- Product Describe

-

RLH-401 model

Hot Air Aging Test Chamber

Instruction Manual

I. Overview

The thermal aging chamber is a product designed and manufactured in accordance with national standards. It boasts a range of advantages, including customizable dimensions, lightweight construction, excellent thermal insulation performance, and more. It features automatic cold-end compensation, superior vibration and interference resistance, and automatic temperature control with high accuracy in both temperature measurement and regulation.

This chamber provides high-temperature operating conditions for industrial production and research institutions, and is primarily used for hot-air aging tests on rubber, rolled materials, wires and cables, and plastic specimens.

II. Structural Description

The cabinet is constructed with cold-rolled steel sheets. The space between the working chambers is filled with aluminum silicate fiber cotton and asbestos boards as thermal insulation layers. The electric heater uses DRB corrugated carbon-silicon far-infrared radiators, which deliver remarkable energy-saving performance. A built-in blower has been added to provide automatic air circulation, ensuring more balanced airflow. A digital display controller is used to execute various programs, and the temperature inside the cabinet is displayed digitally.

III. Technical Parameters

1. Power supply: 220V

2. Power: 2.5 kW

3. Internal dimensions: 45×45×55; turntable rotation speed: 5-10 r/min

4. Controllable temperature: Room temperature to 200℃; Accuracy: 1℃

5. External dimensions of the instrument: 83*66*136 cm,

6. Volume and weight: 0.96 cubic meters, 57 kg

4. Instructions for Use

(1) Connect all the leads of the aging chamber properly, place the test specimens inside, and use a megohmmeter to verify that the insulation resistance should be greater than 2 megohms.

(2) Press the setting button on the control instrument and adjust it to the desired temperature. If the display is digital, set the temperature by pressing the corresponding numbers until you reach the desired value.

(3) Connect the power supply and turn on the power switch. At this point, the green light will illuminate, indicating that heating has begun. At the same time, turn on the automatically speed-regulating blower. The blower’s wind speed is adjustable, and the rotating disc will follow along as it turns.

(4) Once the temperature inside the workspace reaches the desired level, the temperature controller will operate in a constant-temperature mode.

(5) After using the instrument, release all the hot air from the working chamber, return all switches to the “off” position, disconnect the power supply, and wipe dry with a cloth.

V. Product Applications

The hot-air aging chamber can be used to evaluate and determine the adaptability of electrical and electronic products or materials when stored and used under conditions of temperature cycling and high-temperature aging environments on their surfaces. The equipment employs forced air circulation to ensure uniformity of temperature within the working chamber.

VI. Precautions

When using a new aging box or after it has been left unused for an extended period, you should check for any damage and perform an insulation resistance test. The insulation resistance between each live part and the enclosure, as well as between phases, should be greater than 2 megohms. Ensure that the connections between the aging box and the power supply are secure; otherwise, poor contact could lead to damage. Regarding the electrical circuitry, this box is strictly prohibited from containing flammable materials to prevent accidents.

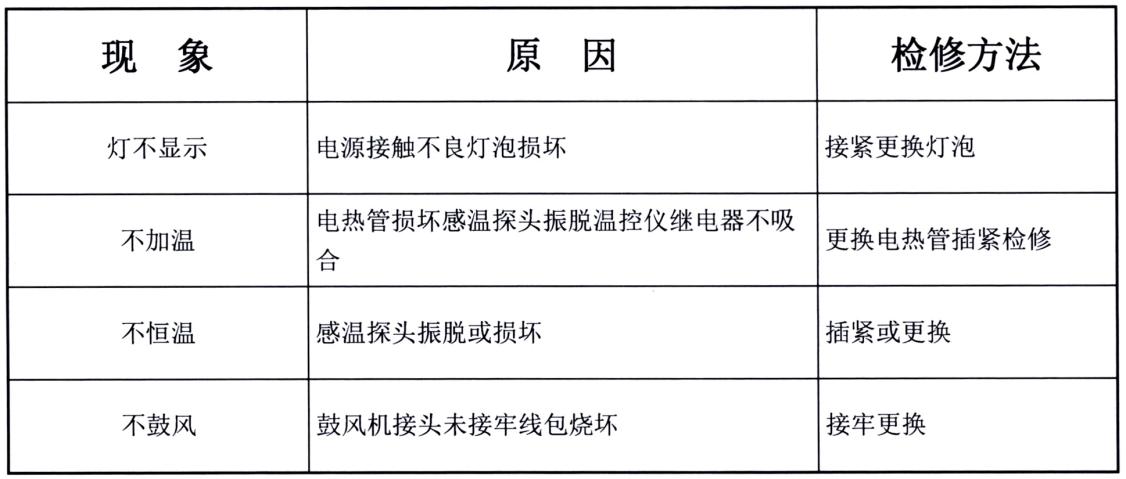

7. Troubleshooting

Company Profile

Hebei Yinfeng Experimental Instrument Co., Ltd. is a high-tech enterprise dedicated to the research and development, production, and sales of experimental instruments. The company is headquartered in Hebei Province, relying on the strong industrial foundation and technological innovation resources in the Beijing Tianjin Hebei region. It is committed to providing high-precision and high reliability testing equipment and solutions for material testing, engineering quality control, scientific research experiments and other fields.

Customized Delivery Process

We provide customers with full-process services ranging from pre-sale consultation, customized solution design, equipment installation and commissioning to after-sale technical support.

Online Communication

Provide Custom Drawings

Merchant Quotation

Sign A Contract

Processing And Production

Packaging And Distribution

Confirm Receipt Of Goods

Successful Transaction

Previous:

RLH-401 Thermal Air Aging Test Chamber

If you need customized products, Contact US !

Tag list

Request a Quote

We will contact you within one working day. Please pay attention to your email.

Related Products

Content update in progress