- Product Describe

-

Overview

The steel pipe bending testing machine is an ideal device for specialized bending tests on steel pipes with an outer diameter not exceeding Φ60.3. This equipment is based on GB/T244-2020 ISO8491:1986 (E) "Metal Pipe Bending Test Methods". Welded steel pipes for low-pressure fluid transportation GB/T 3091-2001 This product is widely used in metal pipe factories, pipeline enterprises, and construction quality inspection departments to test the bending performance of steel pipes.

This steel pipe bending testing machine consists of seven parts: frame, workbench, rotating working arm, steel pipe bending die, cycloidal pinwheel reducer, radial clamping device for steel pipes, electrical controller, etc. It features a compact structure, touch screen display, simple operation, high load capacity, smooth operation, low noise, real-time bending angle display, intuitive interface, safety and reliability, and easy maintenance.

Working principle of this testing machine: one end of the steel pipe is fixed, and the other end rotates clockwise around a specialized bending die. Using digital integrated circuits, the bending angle is obtained from the motor's high-speed shaft through photoelectric pulse shaping and frequency division, then angle counting and continuous cumulative display are performed. When the working disk reaches the preset angle, the control circuit cuts off power to the braking motor to stop rotation.

Main technical parameters

Maximum diameter of bent steel pipe: Φ60.3

Forward bending angle: arbitrarily set within 0—90°

Reverse bending angle: arbitrarily set within 0—90°

Working disk speed: ≤0.4 rad/s

Motor power: 1.5 kW

Machine dimensions (cm): 155×111×150

Main machine weight: 808 Kg

Electrical working principle and operation instructions

1. Electrical working principle

The electrical control system of this testing machine uses digital integrated circuits. The bending angle is obtained from the motor's high-speed shaft through photoelectric pulse shaping and frequency division, then angle counting and continuous cumulative display are performed. When the working disk reaches the preset angle, the logic circuit controls the braking motor to cut off power and stop rotation.

2. Operation instructions

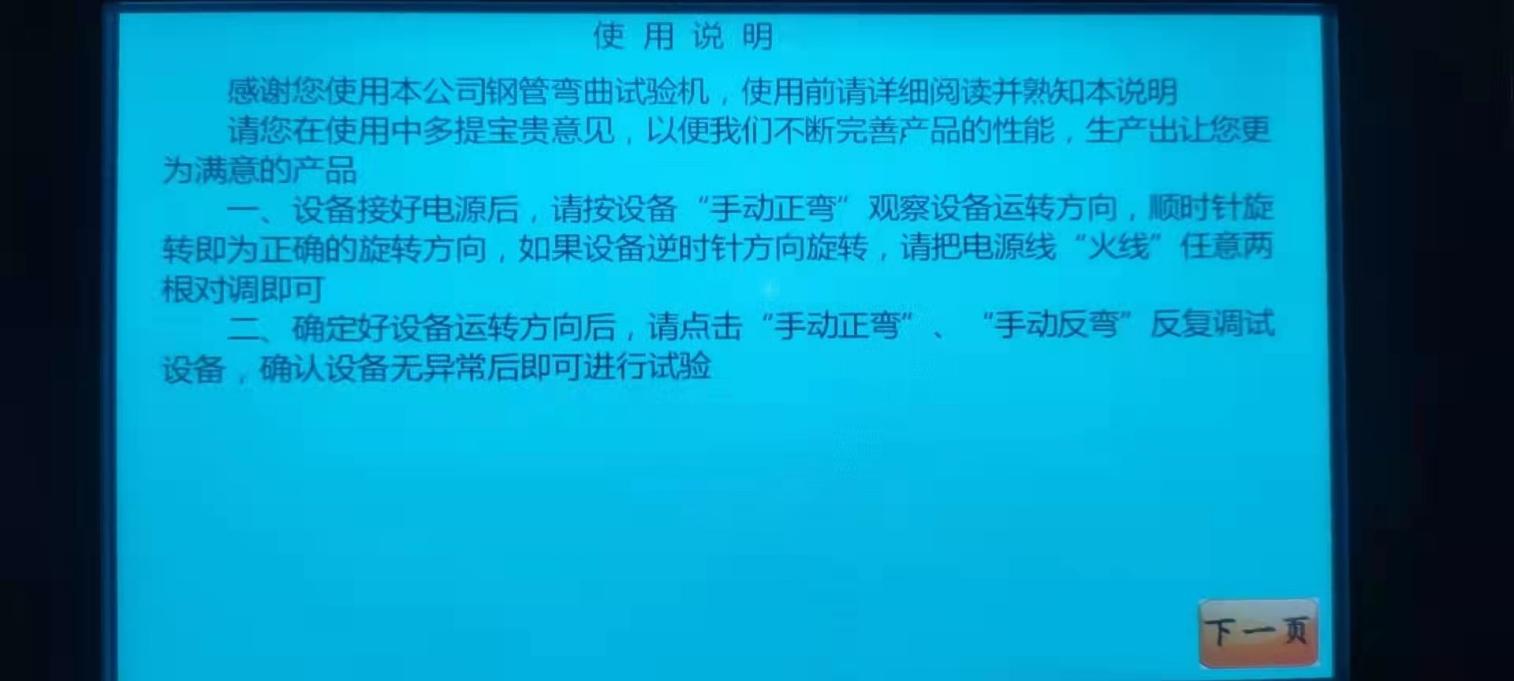

2.1 Startup interface

2.1 Startup interface After powering on the device, the screen displays the startup interface [as shown below]

Press the button to enter the operation interface

Press the button to enter the operation interface

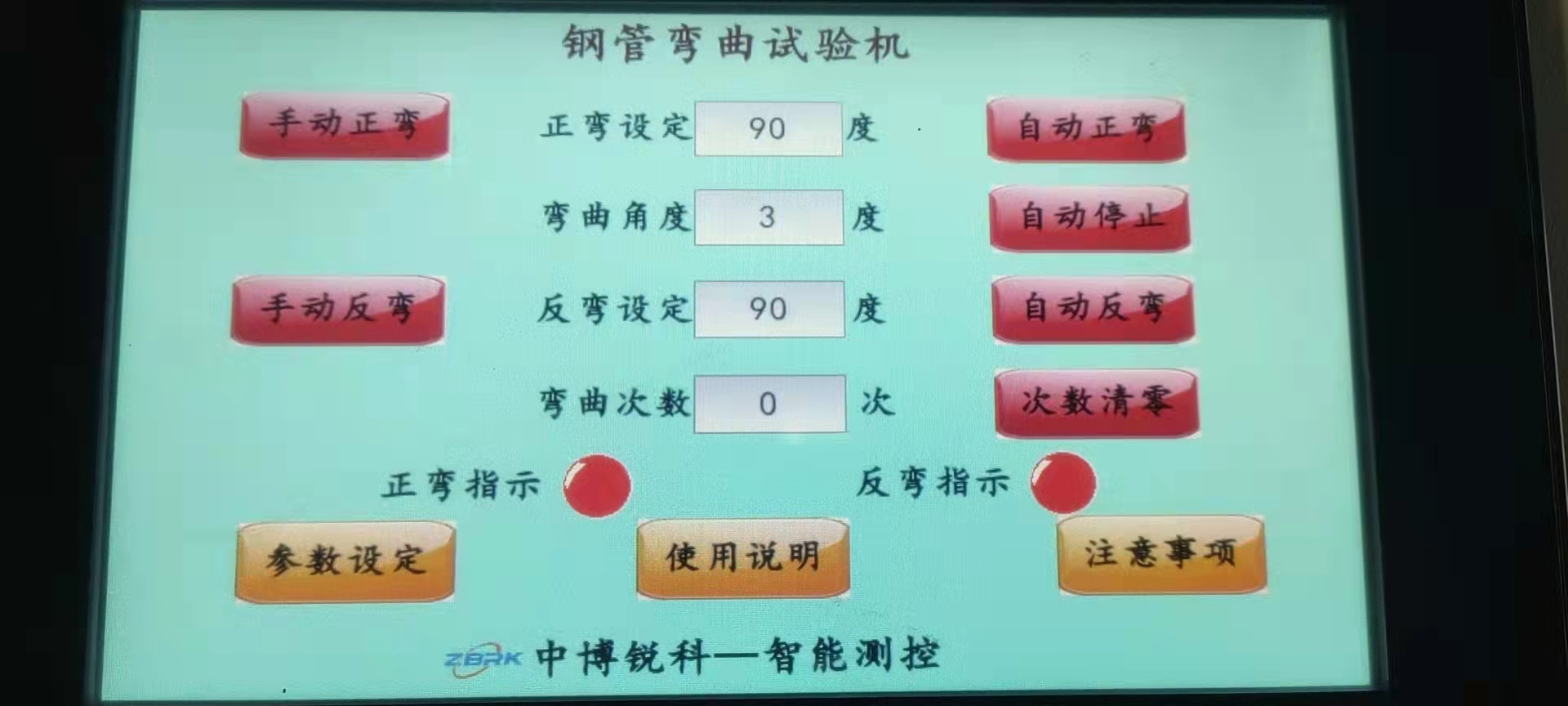

5.2 Operation interface

Angle display: real-time display of the steel pipe bending angle.

Reset button: resets the angle display to zero.

Operation indicator: shows whether the steel pipe is bending forward or backward.

Angle settings:

1) Forward bend: set the forward bending angle.

2) Reverse bend: set the reverse bending angle.

Jog forward bend: jog forward bending; before forward bending, adjust the distance between the working shaft and the steel pipe to bring them closer.

Jog reverse bend: jog reverse bending; before reverse bending, adjust the distance between the working shaft and the steel pipe to bring them closer.

Automatic forward bend: automatic forward bending; the device automatically stops when the preset forward bending angle is reached.

Automatic reverse bend: automatic reverse bending; the device automatically stops when the preset reverse bending angle is reached.

Stop button: press to stop bending during automatic forward or reverse bending.

Parameter settings: can switch to the parameter settings interface.

5.3 Parameter settings

Set device parameters:

Forward bending angle: set the forward bending angle as in the operation interface.

Reverse bending angle: set the reverse bending angle as in the operation interface.

Limit protection: device soft limit protection.

Parameter settings: can switch to the parameter settings interface.

Operation

Preparation: The steel pipe bending testing machine should be placed or installed on a stable foundation. After the whole machine is installed, a trial run should be conducted: before powering on, check whether all parts of the device are normal and whether the power supply is stable. Then, with no parts on the working disk, power on and perform various (jog, automatic) operations (Note: here, clockwise rotation of the working disk is forward rotation, counterclockwise is reverse rotation. If the rotation direction does not match the control buttons, swap any two of the three-phase power lines). After becoming familiar with the machine operation, normal operation can proceed.

1. Basic operation steps of the steel pipe bending testing machine:

(1) Select the appropriate bending die sleeve, rotating sleeve, and pipe clamp seat according to the nominal diameter of the specimen.

(2) Install the selected bending die sleeve, rotating sleeve, and pipe clamp seat on the working disk as shown in attachments 1 and 2.

(3) First turn on the power switch of the bending testing machine, then turn on the control panel switch.

(4) Set the forward and reverse bending test angles on the control panel.

(5) After the test is completed, clean the workbench to ensure the equipment is tidy.

2. Automatic forward bending test

(1) Place the bending specimen on the bending die of the bending machine, and fix the rotating sleeve according to the specimen diameter principle (see attached figure 2).

(2) Use the hand crank clamp arm of the bending testing machine to clamp the specimen tightly;

(3) On the test machine operation panel, set the working state to forward bending, then press the "Jog Forward Bending" button to move the working shaft close to and contact the specimen.

(4) When the working shaft contacts the specimen, press the "Automatic Forward Bending" button. The test machine will automatically perform forward (clockwise) bending, continuously displaying the current bending angle. When the bending reaches the set forward bending angle, the test machine will automatically stop.

(5) After the test machine stops bending, set the working state on the operation panel to reverse bending, press the "Jog Reverse Bending" button while retracting the hand crank clamp arm of the bending test machine, then release and remove the specimen.

(6) Press the "Zero" button on the test machine operation panel to reset the angle display to zero for the next test.

Maintenance of the test machine

- The two-stage cycloidal pinwheel reducer uses lithium-based grease lubrication, which should be replaced every 4 to 5 years.

- Keep the test machine clean.

- When the machine is not used for a long time, apply anti-rust oil on the surface of the working disk and store it in a dry place.

- Do not disassemble integrated circuits and printed circuit boards while powered.

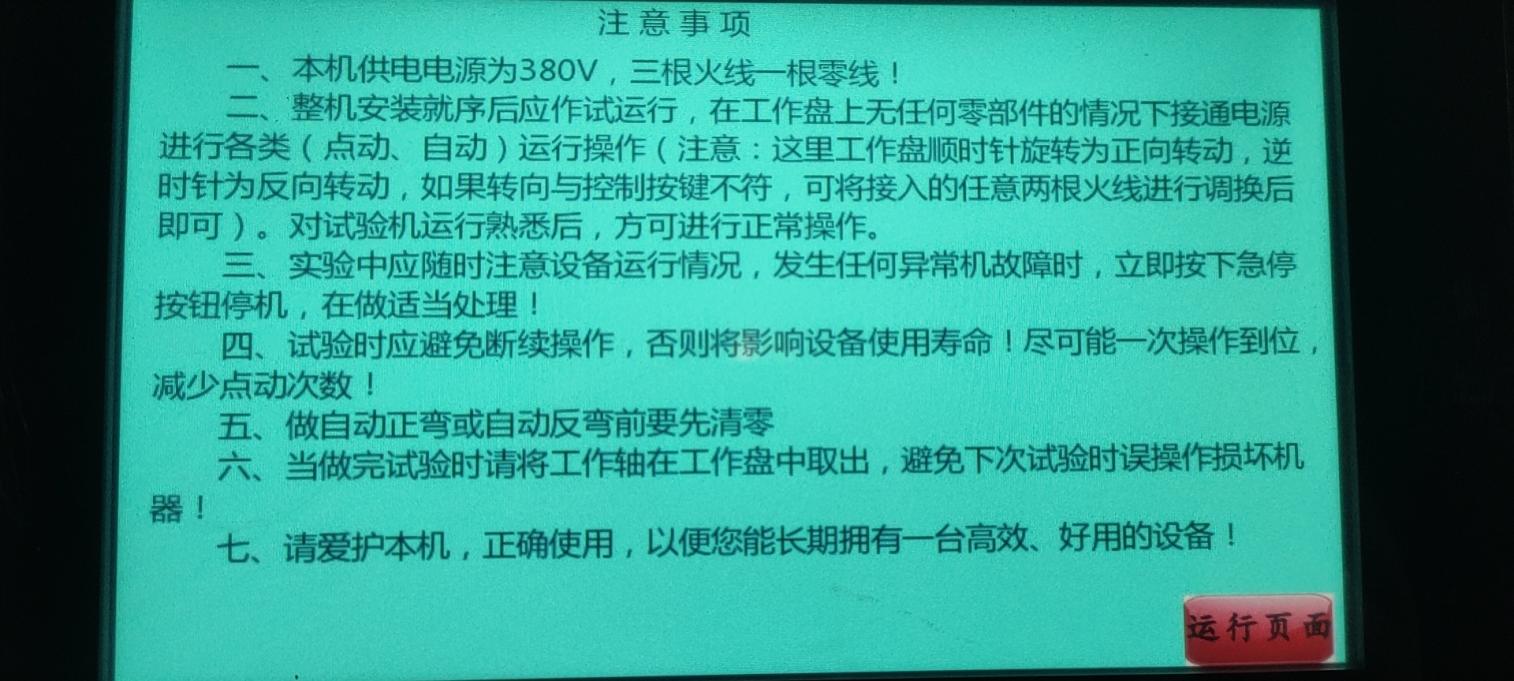

Precautions

1. When testing the machine after unpacking, first remove all working shafts and bending sleeves from the working disk, then operate it without load (untrained personnel should be cautious when starting the machine). Press "Jog Forward Bending," "Jog Reverse Bending," "Automatic Forward Bending," and "Automatic Reverse Bending" respectively, and observe whether the rotation direction and angle of the working disk match the settings. If the rotation direction of the working disk is opposite to the set bending direction, cut off the power and have electrical personnel swap the motor power phases.

2. During the test, the operator must not leave the equipment site and must always monitor the test process. If any abnormal phenomena are found during testing or operation, immediately press the emergency stop button to cut off the main power. The machine can only be used again after professional personnel have debugged and repaired it.

3. When folding the handle of the handwheel, first pull it outward before folding. Do not forcibly fold it directly.

Packing List

Equipment Model: GGW-65 Serial Number:

No. Name Quantity Remarks 1 Main Machine 1 unit 2 Product User Manual and Packing List 1 copy each 3 Product Certificate of Conformity 1 copy 4 Working Shaft 1 piece 5 Random Tools 1 set Hex Wrenches (sizes 5#, 10#, 12#, one each) 5 Bending Sleeve 1 piece each Φ21.3*6, Φ26.7*6, Φ33.4*6, Φ42.2*6, Φ48.3*6, Φ60.3*6, Φ21.3*8, Φ26.7*8, Φ33.4*8, Φ42.2*8, Φ48.3*8, Φ60.3*8 6 Rotating Sleeve (including fastening screws) 1 piece each Φ21.3, Φ26.7, Φ33.4, Φ42.2, Φ48.3, Φ60.3 7 Clamp Tube Seat 1 set each Φ21.3, Φ26.7, Φ33.4, Φ42.2, Φ48.3, Φ60.3 Note: Other specifications of bending sleeves (or bending shafts) can be ordered separately by the user according to their needs.

Company Profile

Hebei Yinfeng Experimental Instrument Co., Ltd. is a high-tech enterprise dedicated to the research and development, production, and sales of experimental instruments. The company is headquartered in Hebei Province, relying on the strong industrial foundation and technological innovation resources in the Beijing Tianjin Hebei region. It is committed to providing high-precision and high reliability testing equipment and solutions for material testing, engineering quality control, scientific research experiments and other fields.

Customized Delivery Process

We provide customers with full-process services ranging from pre-sale consultation, customized solution design, equipment installation and commissioning to after-sale technical support.

Online Communication

Provide Custom Drawings

Merchant Quotation

Sign A Contract

Processing And Production

Packaging And Distribution

Confirm Receipt Of Goods

Successful Transaction

Previous:

Next:

Steel Pipe Bending Testing Machine

If you need customized products, Contact US !

Category

Tag list

Request a Quote

We will contact you within one working day. Please pay attention to your email.

Related Products

Content update in progress