- Product Describe

-

Vulcanized Rubber Compression Deformation Apparatus

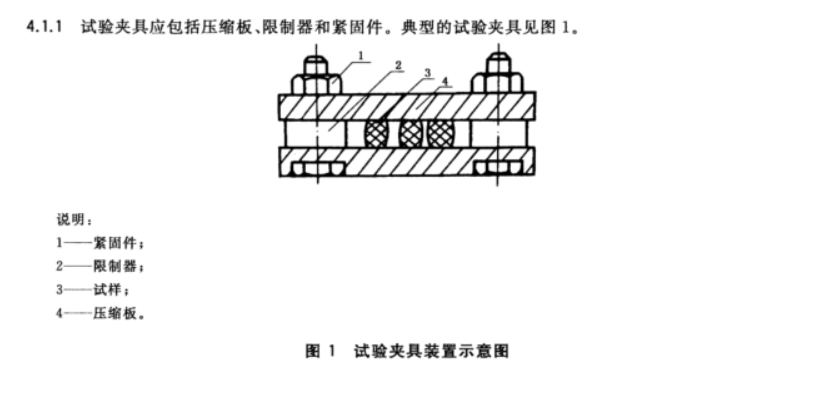

1. The compression plates consist of a pair of parallel, flat, high-gloss steel plates, between which the specimen is compressed. The surface roughness Ra of the compression plates shall not exceed 1.6 μm.

- The compression plates shall have: sufficient rigidity to ensure that they do not deform under compression; steel plates are recommended. They shall also be large enough in size to ensure that, when the specimen is compressed between the two plates, the entire specimen remains entirely within the area covered by the compression plates.

- The limiter provides the corresponding compression ratio.

- The shape and dimensions of the restrictor should be designed to avoid contact with the compressed specimen. The recommended heights for the restrictor are (8 ± 0.02) mm, (7 + 0.02) mm, or (6 ± 0.02) mm; the selection of the restrictor height should meet the requirements for the specimen compression ratio.

- A fastener is a threaded device consisting of a bolt and a nut.

6. Dimensions: The specimen is cylindrical, with a diameter of (10 ± 0.2) mm and a height of (10 ± 0.2) mm. The height difference among specimens within the same group shall not exceed 0.05 mm.

7. Preparation of Specimens: The specimens shall be directly vulcanized using molds. Their surfaces must be smooth and mutually perpendicular and parallel. The specimens should be free of bubbles, impurities, or damage. Alternatively, specimens may be cut from vulcanized rubber sheets meeting the thickness requirements specified in 5.1 using a circular cutter with an inner diameter of (10.2 ± 0.02) mm. During the cutting process, the blade of the cutter may be lubricated with a neutral soap solution, and the cutter should be advanced slowly to minimize any taper in diameter.

Samples prepared using the different methods mentioned above may yield varying test results, making the test results incomparable.

Samples prepared using the different methods mentioned above may yield varying test results, making the test results incomparable.

Company Profile

Hebei Yinfeng Experimental Instrument Co., Ltd. is a high-tech enterprise dedicated to the research and development, production, and sales of experimental instruments. The company is headquartered in Hebei Province, relying on the strong industrial foundation and technological innovation resources in the Beijing Tianjin Hebei region. It is committed to providing high-precision and high reliability testing equipment and solutions for material testing, engineering quality control, scientific research experiments and other fields.

Customized Delivery Process

We provide customers with full-process services ranging from pre-sale consultation, customized solution design, equipment installation and commissioning to after-sale technical support.

Online Communication

Provide Custom Drawings

Merchant Quotation

Sign A Contract

Processing And Production

Packaging And Distribution

Confirm Receipt Of Goods

Successful Transaction

Previous:

GBT1683 Compression Set of Vulcanized Rubber

If you need customized products, Contact US !

Category

Tag list

Request a Quote

We will contact you within one working day. Please pay attention to your email.

Related Products

Content update in progress