- Product Describe

-

Overview

The concrete rebound hammer is driven by a spring to strike the hammer and uses the instantaneous elastic deformation recovery force generated by the impact rod striking the concrete surface to drive the hammer to rebound and indicate the rebound distance with a pointer. The rebound value (the ratio of the rebound distance to the distance from the hammer to the impact rod before impact, expressed as a percentage) is used as one of the indicators related to the compressive strength of concrete to estimate the concrete's compressive strength. It is an instrument used for non-destructive testing of the compressive strength of concrete in structures or components.

Due to the rebound hammer being lightweight, flexible, inexpensive, not requiring power, and easy to operate, it is very suitable for use on construction sites. Additionally, the formulation and implementation of corresponding rebound hammer calibration procedures and technical regulations for testing concrete compressive strength by rebound method ensure its testing accuracy. It is now widely used across various industries in our country.

The HT-225A rebound hammer produced by our company is a medium-sized rebound hammer with a standard energy of 2.207J and a pointer direct-reading indication system. Its technical performance and main parameters comply with the national metrological verification regulation "Rebound Hammer Calibration Regulation" (JJG817-2011). After years of experience accumulation, based on customer feedback and actual usage, we have made multiple technical upgrades. The upgraded rebound hammer is lighter, more durable, and more accurate.

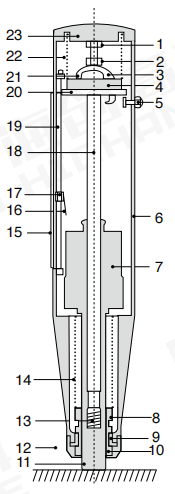

Structure of the Rebound Hammer

1 - Lock Nut

2 - Zero Adjustment Screw

3 - Hook

4 - Hook Pin

5 - Button

6 - Casing

7 - Impact Hammer

8 - Tension Spring Seat

9 - Snap Ring

10 - Dust Seal Ring

11 - Impact Rod

12 - Cap

13 - Buffer Compression Spring

14 - Impact Tension Spring

15 - Scale

16 - Pointer Plate

17 - Pointer Block

18 - Central Guide Rod

19 - Pointer Shaft

20 - Guide Flange

21 - Hook Compression Spring

22 - Compression Spring

23 - Tail CoverOperation, Maintenance, and Calibration of the Rebound Hammer

Operation

1. Press the impact rod against the concrete surface, gently press the instrument to release the button, and when the pressure is released, the impact rod extends out, and the hook catches the impact hammer.

2. Keep the instrument's axis always perpendicular to the concrete surface and apply pressure slowly and evenly. After the impact hammer disengages and strikes the impact rod, the hammer rebounds and drives the pointer to move backward to a certain position. The scale line on the pointer block indicates a certain value on the scale, which is the rebound value.

3. Keep the instrument mechanism pressed against the concrete surface to read and record the rebound value. If conditions are not favorable for reading, press the button to lock the mechanism, then move the instrument to another place to read.

4. Gradually release the pressure on the instrument so that the impact rod extends out of the instrument, ready for the next use.

5. After using the rebound hammer, the impact rod should be extended out of the casing, and dirt and dust on the impact rod, the spherical front end of the rod, the scale surface, and the casing should be cleaned. When not in use, the impact rod should be pressed into the casing. After impact, press the button to lock the mechanism, then place the instrument in its case. The instrument case should be placed flat in a dry and cool place.

Maintenance

Routine maintenance should be performed under any of the following conditions:

1. After more than 2000 impacts;

2. When there is doubt about the test values;

3. When the calibration value of the steel anvil is not qualified.Routine maintenance methods should meet the following requirements:

1. After the impact hammer disengages, remove the mechanism, then remove the impact rod (take out the buffer compression spring inside) and the triple assembly (impact hammer, impact tension spring, and tension spring seat);

2. Clean all parts of the mechanism with kerosene, especially the central guide rod, impact hammer, and the inner hole and impact surface of the impact rod. After cleaning, apply a thin layer of watch oil (or sewing machine oil, transformer oil) on the central guide rod. Other parts should not be oiled.

3. Clean the inner wall of the casing, remove the scale, and check the pointer friction force, which should be 0.5~0.8N;

4. Do not rotate the zero adjustment screw fixed on the tail cover;

5. Do not fabricate or replace parts by yourself;

6. After maintenance, perform calibration tests as required. The calibration value should be 80±2.

Company Profile

Hebei Yinfeng Experimental Instrument Co., Ltd. is a high-tech enterprise dedicated to the research and development, production, and sales of experimental instruments. The company is headquartered in Hebei Province, relying on the strong industrial foundation and technological innovation resources in the Beijing Tianjin Hebei region. It is committed to providing high-precision and high reliability testing equipment and solutions for material testing, engineering quality control, scientific research experiments and other fields.

Customized Delivery Process

We provide customers with full-process services ranging from pre-sale consultation, customized solution design, equipment installation and commissioning to after-sale technical support.

Online Communication

Provide Custom Drawings

Merchant Quotation

Sign A Contract

Processing And Production

Packaging And Distribution

Confirm Receipt Of Goods

Successful Transaction

HT-225A Concrete Rebound Tester

If you need customized products, Contact US !

Category

Tag list

Request a Quote

We will contact you within one working day. Please pay attention to your email.

Related Products

Content update in progress